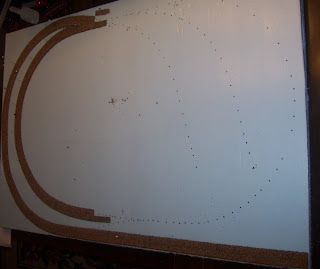

So yes life happens. It's been a while since my previous post about the building of my West Forge practice layout. With all that's been happening in the world I've spent a lot of time working providing my employer with detailed productivity reports to help the hospital staff appropriately and in a cost effective manner, but that's another post. This one is a continuation of what I was working on previously. My 2x3 N scale Pennsy themed layout. In the above picture you can see what became my method of transferring my track plan. I used XTrkCad to print out a 1:1 scale version of my plan, I choose to trim off the excess paper edges and then taped each piece to the blue board in the proper position. I choose to save paper and not print the empty the middle section. Once that was complete I used a thumb tack to poke holes through the plan into the blue board down the center line of all the rails. You can see I also tested the fit of my turnouts to make sure the program had the correct template. Happily it did size all the parts correctly.

In the above picture you can see what became my method of transferring my track plan. I used XTrkCad to print out a 1:1 scale version of my plan, I choose to trim off the excess paper edges and then taped each piece to the blue board in the proper position. I choose to save paper and not print the empty the middle section. Once that was complete I used a thumb tack to poke holes through the plan into the blue board down the center line of all the rails. You can see I also tested the fit of my turnouts to make sure the program had the correct template. Happily it did size all the parts correctly.

In this photo you see the next two steps I took. I used a black sharpie to darken each pin mark just to make it easier for me to see the lines (and it made the work visible for this photo). I then began to fit my cork roadbed into place by following the darkened center line. To hold down the road bed I used yellow wood glue and standard metal straight pins pushed into the shoulder of the roadbed. I made sure to keep the flat top of the roadbed cleared as much as possible so that I wouldn't run into any issues when I installed the track. This was then all left to dry for a few days.

Here you can see the edge of the finished module with the road bed in place. I've added a small cut hillside to the one corner to add some interest The foam layers are again glued together with yellow wood glue and straight pins. You can also see the edge of the foam where I used plain old duct tape to strengthen and protect the side of the foam. While certainly not a nice piece of fascia the duct tape really did help to the protect the sides from getting too banged up while I was working. This is something I will probably do again when working with any exposed foam. The final step for the roadbed was to cover everything with a light tan latex paint. I used just a cheap flat latex that was a pale sand color. While it does look very pale in this picture, and on the module, I still think it was better to go lighter here and let the ground foam darken the scenery later on. After I did this I realized that I'll have to paint most of the layout again anyway because I'm going to put sculptamold (of whatever the name of the generic version I bought is) onto the board to add some visual interest and to make it look less like a flat board, but I also wanted to make sure that the yellow glue holding down the road bed was sealed before I ballasted. This may or may not have been a good idea on my part but I was thinking that the really wet water and glue combo might damage the roadbed or weaken the glue that I used on it. Thinking back I believe that yellow glue is supposed to not be washable by water after it cures/drys so this step was probably not needed, but it still felt good to not be looking at plain old blue foam any more.

The final step for the roadbed was to cover everything with a light tan latex paint. I used just a cheap flat latex that was a pale sand color. While it does look very pale in this picture, and on the module, I still think it was better to go lighter here and let the ground foam darken the scenery later on. After I did this I realized that I'll have to paint most of the layout again anyway because I'm going to put sculptamold (of whatever the name of the generic version I bought is) onto the board to add some visual interest and to make it look less like a flat board, but I also wanted to make sure that the yellow glue holding down the road bed was sealed before I ballasted. This may or may not have been a good idea on my part but I was thinking that the really wet water and glue combo might damage the roadbed or weaken the glue that I used on it. Thinking back I believe that yellow glue is supposed to not be washable by water after it cures/drys so this step was probably not needed, but it still felt good to not be looking at plain old blue foam any more.

So next is going to be track, wiring and ballasting I guess. I'll try and get the next post up before Christmas, but who knows I still have a bathroom to finish repairing between now and then also. As usual please feel free to comment and let me know if you think I could have done something better.

Thursday, December 11, 2008

West Forge: Transferring the Track Plan and Installing the Roadbed

Labels:

Model Railroad,

N Scale,

Pennsy,

Trains,

West Forge

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment